Petro Min Engineers have (over the years) been called upon to provide expertise in resolving electric drive system issues by facilities engineers, drive suppliers and system integrators. The following are recent examples of some of the works carried out successfully.

- 2021 Mine Site Kiln DC drive system fault finding.

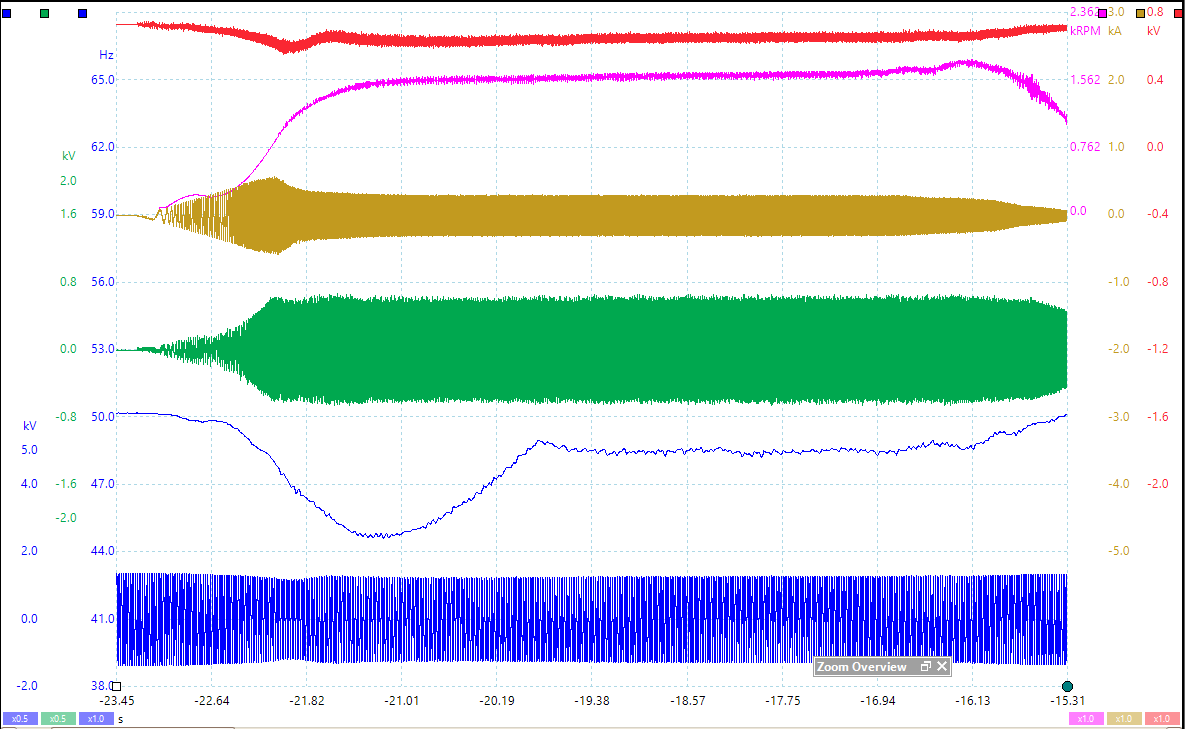

Following an electric storm, where parts of a remote mine site rotating Kiln system received damage from lightning strikes. Personnel experienced difficulties restarting the DC drive system. Following an extended process outage, which lasted several days, Petro Min Engineers were contracted to visit site and troubleshoot the system.

On the first day on site, Petro Min Engineers successfully rectified the system faults and restarted the drive system. The rectification works involved revising the drive system parameters lost during the outage and rectifying issues in the hardware setup.

Petro Min Engineers also provided assistance in updating site records and settings files on all electric drive sites on site and provided training to site electricians on drive theory and operations.